Still with the unit opened, I done a morning ride, roughly 45 minutes at 220W AVG, with some peaks over 500 Watts.

No slipping at all, but let me remark that a local alternative of these common agents destined to increases pulling power and prevents slippage was used, sprayed on the inner face of the belt, last night.

Something similar to these:

The belt becomes sticky and seems to have worked, for how long I am not sure…

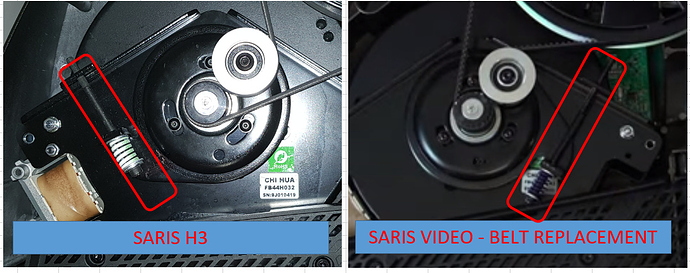

After applying it I released the tension on the screw, mine is on the left, as commented yesterday, I am sure I have not a special unit sent to Portugal, it is just not updated on their site and belt replacement instructables.

Counter clockwise two turns on the screw, more or less.

Again I stress that I have no idea of how far the spring as to be compressed, since using the recommended ¾ gauge seems not feasible for the length of the spring on my unit.

The plastic base of the H3 it shows a square opening that seems tailored for accessing the units with the screw on the right.

After the ride; with no slipping at all, the belt is still more or less centered on the upper pulley.

Deserves to check the comments (from IamHolland) made around the fact that the plate where the tensioner pulley is mounted may not be well aligned.

That plate is well built and strong enough; it is laying on a big plastic spacer that promotes the rotation of the plate when belt tension is applied.

The 3 screws have metallic spacer tubes that seem to have the purpose of assuring that the plate is still able to rotate on further belt tension adjustments.

I think that with proper using of different washers we may be able to achieve a better alignment of that plate and proportionally the belt centring on the big plastic pulley to a reasonable situation.

Lets see…and thanks for all the inputs.

.

.