R2 has great prices but they don’t deliver to the US (at least the items I selected). Any other recommendations for hubs, spokes, and nipples? Thanks.

Hard to say without knowing what you’re trying to get. If you’re in the US you already have access to significantly better pricing on a lot of components than I do.

Have a look on eBay for the pillar spokes. I think they’re cn1423 or something, I’ll have a look a bit later. There’s an outfit in the Netherlands that had lots of nipples, and in the UK. If you’re just after Black or something then again, I imagine eBay or one of the US suppliers would be best.

Sorry I can’t be more useful. There’s at least two American websites that I’ve been on to try and order spokes and nipples as they’re cheaper than anything I could dream of locally but they either wouldn’t ship or were going to charge more than twice the cost of the items to ship.

While I haven’t purchased yet, I’m planning on buying spokes and nipples through wheelbuilder.com and rims from Velocity (Blunt 29). If my budget were slightly higher, I’d be buying We Are One rims. Neither are near the lightest in their class, but both are manufactured in North America at really good prices.

I highly recommend weareone, I run them on my enduro rig and love em! Also a really cool company and all made in Canada!

For a new wheel build, is there a compelling reason to select straight-pull or j-bend spokes? My particular use case is a wheel set for rough gravel / climbs.

The admittedly little I’ve seen on it says that straight-pull wheels can theoretically be stronger than J-bend, but practically speaking it won’t be.

To piggyback off your your question, though, my LBS has said they hate doing straight-pull spokes, as they are a huge pain and require exact tolerances when trimming spokes (before lacing). But I haven’t seen anything similar to this on youtube or other sites. Is lacing up a wheel using straight-pull spokes that much of a pain?

Straight pull spokes are one of the dumbest inventions in bike tech in the last decades and I will die on this hill! Ok there are benefits: lighter, more intuitive to build, some people say stronger (I disagree). I have one friend who is adamant straight pull are better because he once was able to change a spoke while the wheel was still on the bike. But I really think they are off-set by the pretty big cons.

Cons: straight pull are much less used, so sourcing replacement spokes can be annoying. Very unlikely a shop will have a wide variety of straight pull spokes. You also need additional specialized tools for holding the spoke when truing (spoke holder and a nipple spoke wrench), while with J-bend you just need a spoke wrench. Some people also say straight pull doesn’t hold tension as well because they can unwind (there is no J-bend elbow to stop the spoke from spinning).

Straight pull is actually way easier to lace as the spoke holes on the hub just point at the destination on the rim. I think they are very annoying if you don’t have the exactly right spoke length, which is a problem at many bike shops as they often start with blank spokes that they cut to the length they need. Lots of those spoke cutting machines (especially the older ones that have had tough lives) can be off a 1-2 mms.

Straight pull seem much harder to tension without twisting, especially if not bladed. They also can’t be laced in different patterns etc.

They’re easier to lace, as I understand it, as the spokes will end up pointing where they need to go.

I’ve only used J-Bend. Straight Pull I think looks cool and the hubs are lighter.

I wonder if a straight pull spoke might be a lot easier to replace in situ compared a J-Bend that won’t go passed a cassette or rotor.

Thanks for the responses on j-bend vs straight-pull. I’ll go with j-bend.

Next questions:

- What spoke length do I choose if the calculator recommends 291mm but spokes are only available in even lengths (eg 290mm or 292mm)? I used the ProWheelBuilder calculator since it had the dimensions of the hubs already in its database.

- Also, what length nipples - 12mm or 14mm?

Here’s the build that I’m thinking about.

- BTLOS ARL29 rims (29mm deep, 31mm ext, 25mm int, 581mm erd)

- Bitex BX106F front hub

- Bitex BX106R rear hub

- Sapim PolyAx brass nipples (12 or 14 mm)

- Sapim CX-Ray spokes

- 24 holes

Thoughts?

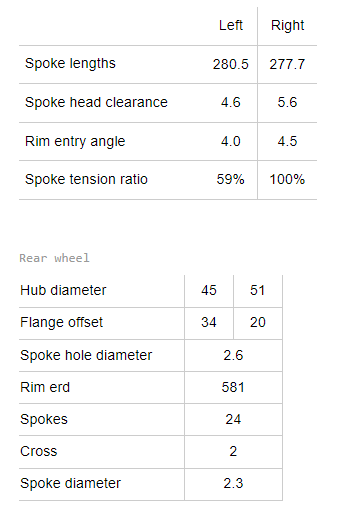

Always always go longer if there’s a question. Assuming you’re talking about 2x and 24 spokes on both wheel, the only calculator I use ( https://spokelength-project.com/calculator/ ) says -

Front:

- I’d go 280/282 or maybe just 282 both sides for this one

Rear:

- This would make sense with 282/280 for me.

P.S: When I buy the Sapim spokes, they come by default with the double square nipples - here they are on the site you linked:

They’re much stronger so you can use alloy with no issues, they’re also pre treated so you don’t need to oil the threads etc.

Hope that helps!

I’ve build 2 MTB wheelsets for myself, so far from experienced, but they have both held up very well. But I don’t agree on the straight pull hate here… They only reason I can think of to prefer jbend is the availability.

First set was tune lefty front hub, hope pro 4 rear hub, nextie (chinese) carbon rims and round (no need for bladed on MTB) J-Bend sapim d-light spokes (between DT comp and race with 2.0/1.65/2.0)

building was fine, hubs where pretty round, so fairly easy to get right. Without experience, correct lacing takes a lot of time and focus ![]()

Didn’t use a nipple driver, so that was the biggest mistake and (in hindsight) made is more difficult to get it even.

Second set, spend a bit more on parts, duke hubs and rims, and hub where straight pull, so used sapim straight pull d-light spokes (same as first build, but then straigh pull instead of j-bend).

Lacing was very-very easy, just push the spokes through the holes, make sure you weave (over/under) them correct, but they will point in the right direction automatically. Put it in the middle of the rim and line up your logo and valvel hole and start screwing on the nipples. took me WAY less time as with j-bend

What also took me way less time was using a nipple driver. Getting the nipples on all spokes with the same base tension is a pretty important starting point. I got an adjustable driver bit, which was worth every cent (I think it was 25 euro)

In both cases I haven’t done anything special to prevent spoke twist, except from de-stressing the spokes often (pinching spoke pairs, pushing , etc ) and I haven’t noticed anything different with regards to twisting beween jbend and sp.

So I might be just lucky, or it’s the de-stressing part that eliminates this problem…

I followed Roger Mussons steps from his book, which is the best there is for people who want to understand what they are doing ![]()

@alexgold123 thank you for this. I used “3 cross” on the ProWheelBuilder calculator. “2 cross” gets me nearly the same lengths as you suggest. Thanks!

Yep, definitely don’t build 3x with these parts. This is what happens when I change it in my calculator:

That’s a cool feature, thanks!!!

I built one straight pull wheel, and will likely never do it again. Yeah, yadda yadda yadda, one could make the idea that a straight pull wheel could be stronger, but it’s not like j-bend wheels are so notoriously weak. The ‘feature’ of building and actually owning a straight pull wheel is needing a spoke holder for building, and even the owner/whomever truing them. The nipples often get ‘stuck’ to the spoke, and trying to true a straight pull wheel can have the entire spoke rotate rather than tighten/loosen the spoke, or even tighten/loosen unevenly. Aside from the need of a holder, it’s laced dished and trued the same as a j-bend. (Someone said, downstream, that they are easier because the hub automatically lines up the spokes in the rim, but it’s not that huge of a deal as you get more experienced, and if you have an existing wheel to use as an example.

I guess I wouldn’t have a huge issue doing a straight pull build again, but it was an experience. (The Roval spoke holder was so helpful! It has a large gripping surface, and is easy to put leverage into holding the spokes)

Depending on the wheel, why not throw Berd into the mix ![]() I have a set on my XC / Marathon Wheels and they’ve been great. Granted, if you break one, much much more limited distribution so you should have spares on hand.

I have a set on my XC / Marathon Wheels and they’ve been great. Granted, if you break one, much much more limited distribution so you should have spares on hand.

Been thinking about picking up a wheel stand and tools to get started here in the new year, so sort of watching this thread from a distance.

First I’ve heard of that. I guess that’s possible if the wheel isn’t tensioned enough? You make it seem like j-bend spokes are junk, and that’s incredibly far from the truth, unless tongue-in-cheek.

What’s a ‘blank spoke’? I haven’t seen one. Yeah, you can use slightly different lengths than what the measurements would indicate, but ‘blank spokes’? Do they then thread them themselves? I don’t get it…

it’s quite common for small wheelbuilders to cut and thread spokes. you don’t have to stock different lengths and it’s not that much work.

(seems to be too much work for a full wheelset when you can wait for an order of spokes coming in, but very usefull for repairs, unusual lengths and out of stock lengths)

I know a hobby builder that uses this pretty often

Straight spokes not holding tension is just something i have heard, I also think its a little ridiculous. If you use spoke prep I can’t really see it being an issue.

Blank spokes are unthreaded, usually 310mm in length, that bike shops with spoke machines buy. If you are a high volume shop, its way easier to just have a couple thousand 310mm spokes in stock, and then cut them and rethread to length when you need one. The downside is these machines are extremely expensive; The Phil Wood is 10k USD!