Seems like a lot on here go with low rolling resistance and minimal traction. I’ve done that experiment and quite frankly miss the grip. Am I the only one or anyone else beefing up the tread?

BRR numbers are great and all, but boy do I love the grip of the fat Barzo front out at Fort Ord.

This is why I was interested in the testing of the Rush actually. I have felt that it doesn’t lose much on grip to something like an Ikon (which I ran for a while before the Rush) but has seemingly lower rolling resistance. And while it didn’t test as well as the Race King and some of the Schwalbe’s, it seemed pretty comparable to some other XC tires like the Mezcal, so I felt it somewhat confirmed what I was feeling. I’m not confident enough in my descending skills to run some of the more minimalist traction tires, so the Rush checks a lot of boxes for me. I’m also interested in other XC tires that have good rolling resistance but don’t sacrifice as much on the traction. So no, you’re not alone in not wanting to give up too much on the traction front.

I already have done my standard rolling test and the Aspen ST 170 2.4 are faster (like 7 percent faster) than both the Rush PRO SCT 2.4 and the RaceKing Protection Black Chili 2.2. AND they offer more cornering grip.

In my testing I wasn’t able to determine if the meaty tires gripped way better or that I was simply going so much slower that every corner was easy. We’re talking 30 seconds slower per 14 minute lap swapping only the front tire!

Joe

I highly doubt that he properly applied statistical analysis to those findings. He was talking about time differences of 0.07% being statistically significant. I call BS. It might be statically significant if the only margin of error you consider is the stopwatch, but it certainly isn’t when you consider the reaction time of the human operating it, the tire pressure accuracy, and most importantly he can’t ensure that he took exactly the same path, resulting in hitting exactly the same bumps and total distance travelled every time.

In fact, he talks about the courses used having slick roots, jumps, etc and only did 2-3 runs per tire (“24 runs across the 3 trails” and 3 tires). Yet draws conclusions about the widths being X.X% faster than each other. That’s preposterous! He can’t possibly claim that level of precision in the results. At best his margin of error is 1%, probably higher.

Using the scientific method is only one small part of correctly investigating something. First of all your experimental design has to be very good, which in this case it wasn’t. Then the scientific method has to be properly applied, which is way harder than it sounds. Next, you have to do all the analysis correctly, also very difficult. Finally and hardest of all is drawing the proper conclusions. That’s why peer review is so important in science, it’s to try to address those potential pitfalls.

But there’s way better controlled testing out there that shows that if tire construction is kept constant and tire pressure is adjusted for equal tire drop then tire width doesn’t affect rolling resistance. And additional testing that shows that hysteresis losses are sensitive to tire width and terrain bumpiness.

The controlled testing you link to is for road tires, tested on a steel drum. That testing is far from real world mountainbike conditions. Believe it is best suited to test the suppleness of the carcass, not impedance losses that are very important in the real world. I am more inclined to believe the conclusions and findings from Silca

Wider, higher volume tires allows for lower air pressures. Leading to less rolling resistance, should you believe their findings.

Agrred and I actually meant to also link the Silca article. My other link was to real world roll down testing with a person.

In context of the BRR conversation, the roller and real world results agree that tire width does not matter (if controlling for same tire deflection) to pure rolling resistance effect of tire construction. That’s my point (besides the YouTube video being a bad).

And we know real world has to account for impedance losses, especially off road. So wider tires at appropriate pressures are going to better, right?

Maybe. One thing the BRR tests are very good at showing is that despite being the same model of tire with supposedly the same specs, there are sometimes still differences in construction that the manufacturer doesn’t tell us.

For example, as the tire gets wider they might increase the tread thickness. Or the various plies might be the same width on a 2.1 vs 2.4 tire resulting in less overlap of the plies on the 2.4, but then the 2.6 uses wider plies and is actually slower than either on the drum. Stuff like that can throw off the actual results compared to expectations. There’s also manufacturing tolerance variation and design changes (undisclosed ones) over time. This is why people keep voting for a sixth variant of GP 5000 instead of something with more variety.

So all that is to say that we must draw all of our understanding of real world fastest tires and pressures from real world data. Just like with training, the best measure of performance is performance itself.

But also, there are useful things that we can learn from roller tests. We can learn half the story, energy loses in the tire, from the roller. This tells us if a given road tire has higher or lower tread and carcass loses. It’s questionable though how much the geometry of different knobs affects the results. But given that knob design doesn’t seem to have a large impact to roller results, it doesn’t seem to matter much.

So look at it this way. Roller testing is like testing new medicines for humans in lab rats. It tells us something useful, but it’s not enough on its own. We have to understand how well those results do and don’t translate to humans to guide our interpretation. We ultimately have to do a human trial to further understand if it’s effective.

But lab rats trials allow more precision (at the cost of accuracy) than human trials do. We can genetically engineer rats in all sorts of manners, completely control their environments, dissect them, etc. You can never get that precision with human trials.

All of that is probably true. I would not be surprised if a carcass hysteresis properties will vary with the width and volume of the tire, due to everything you mentioned. The big question is, is that more or less important than reducing the impedance/bump absorption?

I am sure I am not the only one who has discovered that higher volume tires allow for less air pressure before running into problems with rim strikes or tire roll in corners. From the Silca findings, being able to run low pressures seems to be more important. In fact it suggest I should be running 13.5 PSI, which would be impossible for me to achieve without destroying my rims.

Here is another source of testing, looking into tire pressure. I will not vouch for the testing method, as that is beyond my qualifications. More Speed Less Power

Sorry I missed that.

I’d go with Recon F Ikon R. Since you have those tires, I would even consider testing them as well as combinations. Would throw the Dissector in front just to see what the differences are and have fun analyzing.

I did that last year and while I really like how my front tire performs, I know its a bit slow, so I know looking for similar tire with lower rolling resistance is the right path for me.

Reducing the impedance is clearly the most important once you’re on anything but very smooth surfaces, per the Silca chart, because once you get above that breakpoint the required power goes way up.

But if we’re comparing similar very supple tires in very similar widths and pressures, then we can rely on the BRR results to at least rank which tire should be fastest in real world roll down tests.

Of course a really big factor is how confident you are on the tire on the terrain you will be riding, as well as flat resistance. If you have to brake more or crash or get a flat, saving a few watts was meaningless.

So final conclusion is make a list of the widest tires you can use that fit your needs (traction, handling, durability, price). If you like several of them, the BRR data can tell you which should be faster. That’s the easiest way.

If you can really be super careful with testing you can do your own tests, but chances are all you’ll find out is which tire you were fastest on, not the root cause, at least if you’re testing on XC trails. Maybe it was faster because it led to less braking, better cornering, or really did just roll better. Maybe it was some factor you didn’t control for (fork oil temperature, not taking the same line, etc). If you do enough runs and swap back and forth a lot you at least can say what gave the better performance. At that point you really don’t need to know why, just use it.

I’ll be interested to see how the Aspen ST 170 are in terms of durability and flat protection for you, since Maxxis says the Team Spec tires “are for race use only,” which I interpret more as a hedge vs. a marketing tagline.

Jumping in here… I just put Rekon’s on the front and Rekon Race on the rear. The rear is a 2.4 120 TPI. On my second ride I pinch-flatted (I’m 170lbs and running 25 PSI, no inserts), Replaced the tire and flatted 1st ride on the new tire… I’m really not riding that hard. Do you really have to be super careful picking your lines with the Race? Its pretty rediculous. Are Rekon Race’s junk? Never had this issue with another tire (same trails).

Which Race 60 or 120 TPI? With or without inserts? I’m having horrible luck with the Races, Two tires, two pinch flats…

I respect the investment into trying to get people on the TR forum to understand the concept of testing for controls and variables, but having made the same effort about three times; I promise in four posts someone will come on and say “Oh no but that’s a drum and my MAXXIS Dogshit EXO TR 2.4 is much faster in real life and you’re wrong because Kevin Swindog rides them in my favourite World Series of Gravelbiking Presented by TRUCKS4REALMEN races”. I had the same nause gently offering advice about waxed chains on one thread, aerodynamics on another.

People don’t like cognitive dissonance ![]() .

.

I remember that video, and I guessed which one it was even before clicking on the link. He put a lot of thought and effort into the test, and as you say, it’s a lot more rigorous than most testing that gets done. I liked that he also highlighted the limitations of the testing, which most people don’t do and that’s generally a good sign, that he’s critiquing his own test.

It was that video, five years ago, that motivated me to learn more about statistical methods like T-tests, confidence intervals and uncertainty quantification in general (also for the benefit of my job). I think we could use those sorts of methods more often in the tyre testing we all do, to quantify the effect of the variability we get in results. Instead many of us, myself included, usually rely only on our gut feeling whether one set of test results are sufficiently different to another set of results, to judge whether it’s a meaningful difference or not.

The variability is a real challenge for testing the rolling resistance of MTB tyres. The nature of MTB trails, with rocks and roots makes it difficult to create a controlled test in real world conditions because of the variability in line choice (e.g. did I hit that rock on the last lap?). It’s somewhat easier for testing gravel, and perhaps cyclocross, but MTB trails are tricky. In my own testing, I’ve used a grass field to get less variability, to make it more controlled, but then the test become less representative of bumpy MTB trails. I think there are ways it could be done, but you’d have to build dedicated tyre test trails. The way we try to overcome this, and testers like @Joe do this in the results he has posted in this thread, is lots of A-B-A-B repeats to mitigate the variability. That takes a lot of time and effort to collect the data though. Or alternatively we look to controlled testing like BRR which identifies some of the rolling resistance losses relevant to XC riding, but not all of them.

Somebody recently told me about this Trek tyre testing treadmill machine (video here), which looks very good, and as a test method it looks like it could address some of the weaknesses of BBR type drum testing for bumpy off-road conditions.

Apologies if I missed it but I had the opportunity to view the new new Peyote at a sponsor stand last week. I wouldn’t rider that in anything but dry, its almost a gravel tyre - slick while upright and very small tread outside of the centre.

I also learned the new “XC” grade at Vittoria is a budget version heavier that the Race or TNT’s, relying on a thicker sidewall without the TNT and a single compound rathe than the 4C of the others.

Actually, he didn’t say that. At 18:14 in the video he says, when talking about the 0.07% and 0.14% differences: “…on the rougher and steeper climb I found no significant difference between all of the tyres.”

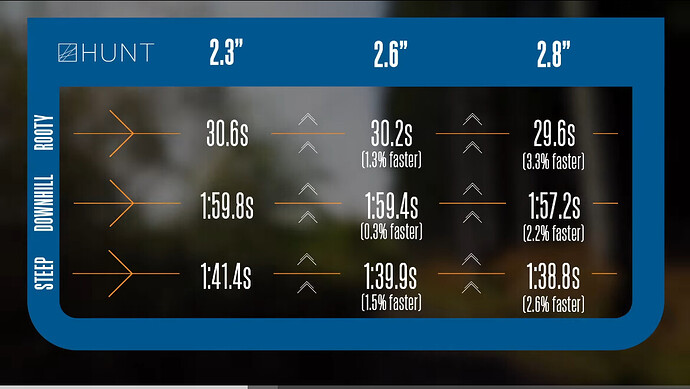

It was instead the smoother climb (at 18:53 in the video), for which the % difference was larger (1.2-1.5%), that he said there was a significant difference relative to to the 2.3" tyre. We don’t have access to his raw data, so we can’t see if he made any mistakes in the processing of the data. To pass the T-test with a 5% probability criteria, and assuming he did a few runs with each tyre, he would need to have need a difference in average times (i.e. the 1.3-1.6s difference) that is about 3 times larger than the combined standard error of the two sets of data.